CNC Meaning: The Complete Guide to Computer Numerical Control Technology

Understanding CNC meaning is crucial for anyone involved in modern manufacturing. CNC technology represents the backbone of precision manufacturing, revolutionizing how we create everything from automotive components to aerospace parts. This comprehensive guide explores the CNC meaning, applications, and the transformative impact of computer numerical control systems in today's industrial landscape.

What is CNC: Fundamental CNC Meaning

The CNC meaning refers to Computer Numerical Control, a revolutionary manufacturing process that uses computerized systems to control machine tools. When professionals discuss what is cnc, they're referring to a sophisticated technology that automates the operation of machine tools through pre-programmed computer software. The CNC meaning encompasses the entire ecosystem of automated manufacturing, where precise instructions guide cutting tools, lathes, mills, and other equipment to create parts with exceptional accuracy.

The evolution of CNC meaning has transformed manufacturing from manual operations to highly automated processes. Understanding the CNC meaning involves recognizing how computer numerical control systems interpret digital instructions to manipulate physical tools. This technology embodies the CNC meaning by converting computer-aided design (CAD) files into precise mechanical movements, ensuring consistent quality and reducing human error in manufacturing processes.

CNC Machine Technology and Operations

Exploring whats cnc technology reveals sophisticated machinery capable of performing complex operations with minimal human intervention. The CNC meaning extends beyond simple automation to encompass intelligent manufacturing systems that can adapt to different materials, tooling configurations, and production requirements. Modern cnc machines demonstrate the full scope of CNC meaning through their ability to execute intricate cutting patterns, drilling operations, and surface finishing tasks with micron-level precision.Optical Transceiver.

CNC Milling Operations

CNC milling exemplifies the core CNC meaning through rotary cutting tools that remove material from workpieces. These operations showcase how CNC meaning translates into practical manufacturing solutions, enabling the creation of complex geometries and surface features that would be impossible with manual machining.

CNC Turning Processes

CNC turning represents another fundamental aspect of CNC meaning, where workpieces rotate while cutting tools shape them. This process demonstrates how the CNC meaning encompasses various machining strategies, from simple cylindrical parts to complex contoured components.

Multi-Axis CNC Systems

Advanced multi-axis CNC systems embody the sophisticated nature of CNC meaning, enabling simultaneous movement across multiple planes. These systems expand the CNC meaning to include complex 3D machining operations that produce intricate parts in single setups.

The terminology c and c machine or c&c machine often appears in discussions about CNC meaning, though these terms may refer to various manufacturing equipment. However, the authentic CNC meaning specifically relates to computer numerical control technology. Professional manufacturers understand that cnc means precision, efficiency, and consistency in production processes, making it the preferred choice for high-quality manufacturing applications.

CNC Device Components and Systems

Understanding CNC meaning requires familiarity with the various components that comprise a complete CNC system. A typical cnc device includes the machine structure, spindle system, control unit, and feedback mechanisms that work together to achieve the precision manufacturing goals inherent in the CNC meaning. These integrated systems demonstrate how the CNC meaning encompasses both hardware and software elements working in harmony.

The control unit serves as the brain of any CNC device, interpreting programming instructions and converting them into precise mechanical movements. This component exemplifies the CNC meaning by bridging the gap between digital design and physical manufacturing. Modern CNC devices incorporate sophisticated feedback systems that continuously monitor and adjust operations, ensuring that the manufacturing process maintains the high standards implied by the CNC meaning.

Machining Processes and CNC Applications

The relationship between machining and CNC meaning is fundamental to modern manufacturing. CNC meaning encompasses all forms of subtractive manufacturing where material is removed from a workpiece to create the desired shape. Traditional machining operations have been revolutionized by CNC technology, with the CNC meaning now extending to include automated setup, tool changing, and quality control processes.

CNC meaning in machining contexts involves the integration of cutting tools, workholding systems, and coolant delivery mechanisms. The comprehensive nature of CNC meaning ensures that all aspects of the machining process are optimized for efficiency and quality. From roughing operations that quickly remove large amounts of material to finishing passes that achieve final dimensions, the CNC meaning encompasses the entire spectrum of machining activities.

CNC Machine Operator Roles and Responsibilities

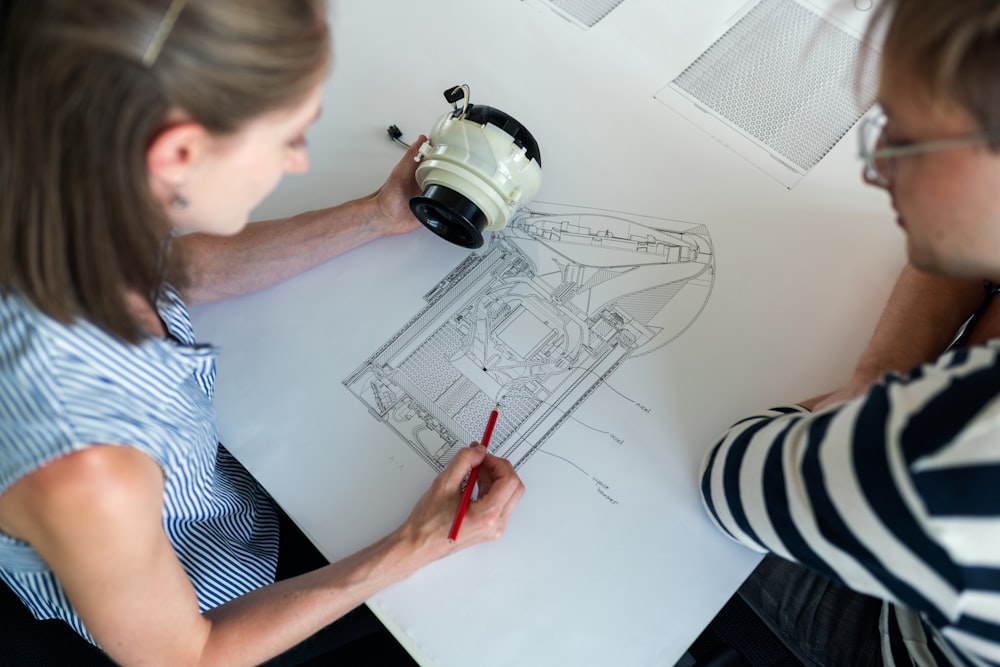

The role of a cnc machine operator is central to realizing the full potential of CNC meaning in manufacturing environments. These skilled professionals understand the practical applications of CNC meaning, translating engineering requirements into programmed instructions that guide machine operations. A competent CNC machine operator must comprehend the technical aspects of CNC meaning while maintaining the operational skills necessary for efficient production.

CNC machine operators serve as the human interface between design intent and manufactured reality, embodying the practical application of CNC meaning. Their expertise ensures that the sophisticated technology implied by CNC meaning translates into consistent, high-quality products. The training and experience of CNC machine operators directly impact how effectively the CNC meaning is realized in production environments.

Advanced CNC Technologies and Future Developments

The evolution of CNC meaning continues to advance with emerging technologies like artificial intelligence, machine learning, and adaptive control systems. Modern interpretations of CNC meaning include predictive maintenance, automated quality control, and intelligent optimization algorithms that enhance manufacturing efficiency. These developments expand the traditional CNC meaning to encompass smart manufacturing concepts and Industry 4.0 integration.

Understanding what are cnc machines in today's context requires recognizing their role as interconnected manufacturing nodes within larger production systems. The contemporary CNC meaning includes networking capabilities, remote monitoring, and data analytics that provide unprecedented visibility into manufacturing processes. This evolution demonstrates how the CNC meaning continues to adapt to changing technological and market demands.

Industry Applications and CNC Meaning Impact

The broad application of CNC meaning across industries demonstrates its fundamental importance to modern manufacturing. From aerospace components requiring extreme precision to automotive parts demanding high-volume production, the CNC meaning encompasses diverse manufacturing requirements. Medical device manufacturing particularly benefits from the precision and consistency implied by CNC meaning, where product quality directly impacts patient safety and treatment outcomes.

Aerospace Manufacturing

In aerospace applications, CNC meaning translates to the precision manufacturing of critical components where failure is not an option. The stringent requirements of aerospace manufacturing fully utilize the capabilities inherent in CNC meaning, producing parts with exceptional accuracy and surface finish.

Automotive Production

The automotive industry exemplifies the mass production aspect of CNC meaning, where efficiency and consistency are paramount. CNC meaning in automotive contexts includes high-speed machining operations and automated part handling systems that maximize throughput while maintaining quality standards.

Medical Device Manufacturing

Medical device production showcases the precision and reliability aspects of CNC meaning, where every component must meet strict regulatory requirements. The CNC meaning in medical applications encompasses specialized materials, ultra-precise tolerances, and documented quality control processes.

Economic Impact and CNC Meaning Significance

The economic implications of CNC meaning extend far beyond individual manufacturing operations to encompass entire industrial sectors. Companies that effectively implement CNC meaning principles gain competitive advantages through reduced production costs, improved quality, and enhanced manufacturing flexibility. The global adoption of CNC meaning has fundamentally altered manufacturing economics, enabling cost-effective production of complex parts that were previously prohibitively expensive.

Investment in CNC technology represents a commitment to the principles embodied by CNC meaning, including precision, efficiency, and quality. Organizations that embrace the full scope of CNC meaning often experience improved customer satisfaction, reduced warranty claims, and enhanced market competitiveness. The return on investment associated with CNC meaning implementation typically justifies the initial capital expenditure through improved operational efficiency and product quality.

Training and Education in CNC Meaning

Proper education and training are essential for maximizing the benefits associated with CNC meaning. Technical schools and universities offer specialized programs that teach the theoretical and practical aspects of CNC meaning, preparing students for careers in modern manufacturing. These educational programs ensure that future manufacturing professionals understand both the technical capabilities and operational requirements implied by CNC meaning.

Continuous learning remains crucial in the rapidly evolving field encompassed by CNC meaning. Manufacturing professionals must stay current with new technologies, programming techniques, and industry standards to maintain their effectiveness. The dynamic nature of CNC meaning requires ongoing education and skill development to remain competitive in the modern manufacturing landscape.

Quality Control and CNC Meaning Standards

Quality control processes are integral to the CNC meaning, ensuring that manufactured parts meet specified requirements and customer expectations. The precision capabilities inherent in CNC meaning enable the implementation of sophisticated quality control measures, including statistical process control and real-time monitoring systems. These quality assurance practices demonstrate how CNC meaning extends beyond simple manufacturing to encompass comprehensive production management.

International standards and certifications play a crucial role in defining and maintaining the quality aspects of CNC meaning. Organizations like ISO and ANSI establish guidelines that ensure consistency and reliability in CNC manufacturing processes. Compliance with these standards validates the implementation of CNC meaning principles and provides confidence to customers and stakeholders.Electronic shelf labels.

Environmental Considerations and CNC Meaning

The environmental impact of manufacturing has become increasingly important, and CNC meaning includes considerations for sustainable production practices. Modern CNC systems optimize material usage, reduce waste generation, and minimize energy consumption, aligning with environmental stewardship goals. The efficiency inherent in CNC meaning contributes to more sustainable manufacturing practices by reducing resource consumption and environmental impact.Related Hydraulic Spare Parts.

Green manufacturing initiatives often leverage the precision and efficiency aspects of CNC meaning to minimize environmental footprint. By optimizing cutting parameters, reducing scrap rates, and implementing efficient coolant systems, manufacturers can achieve environmental goals while maintaining the quality and productivity benefits of CNC meaning. This integration of environmental consciousness with CNC meaning principles demonstrates the holistic approach required for sustainable manufacturing. Related Lithium Battery Manufacturing.